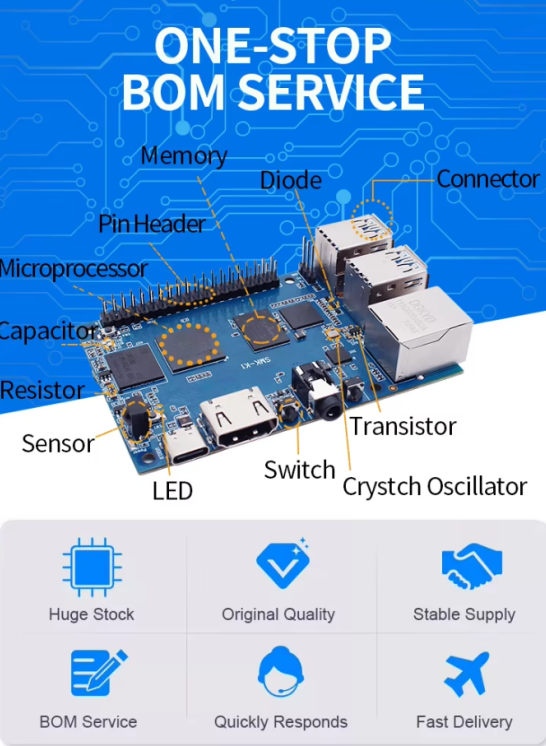

OUR SERVICE

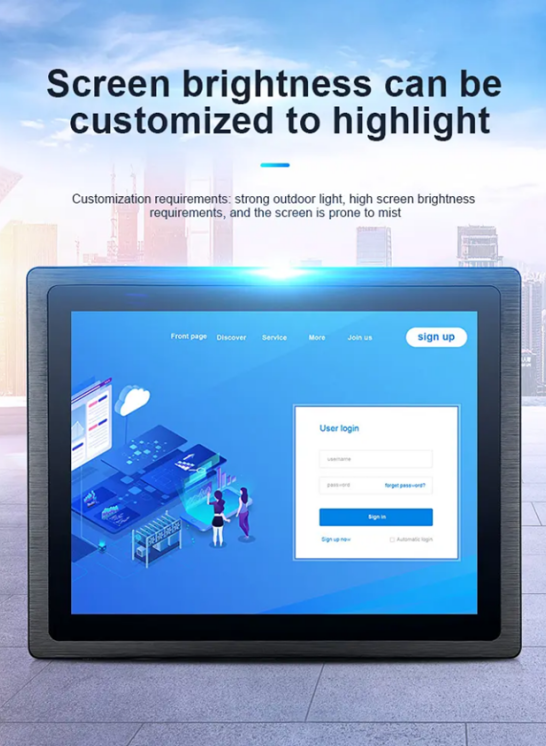

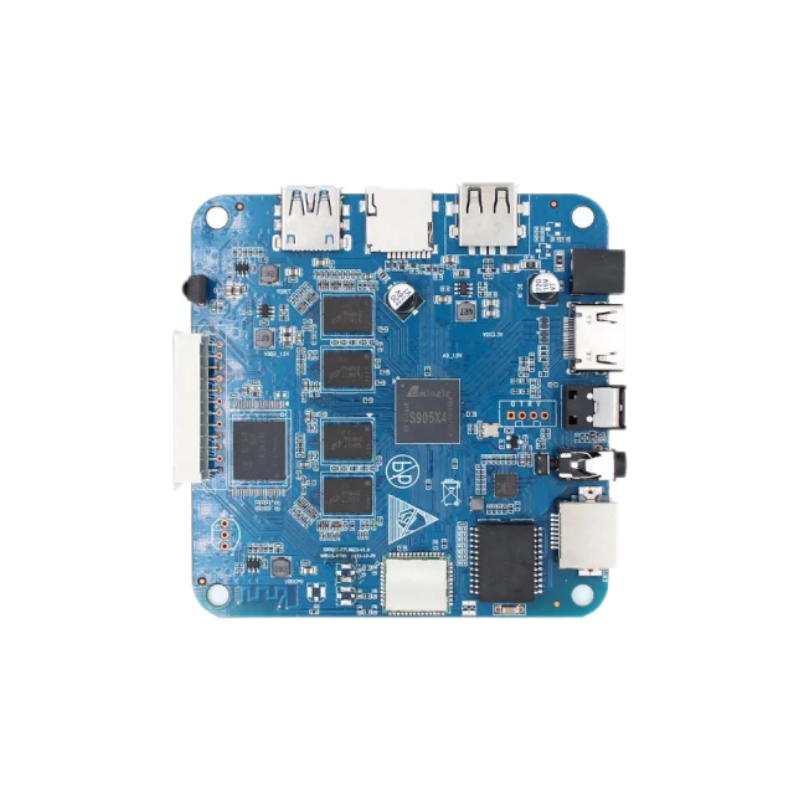

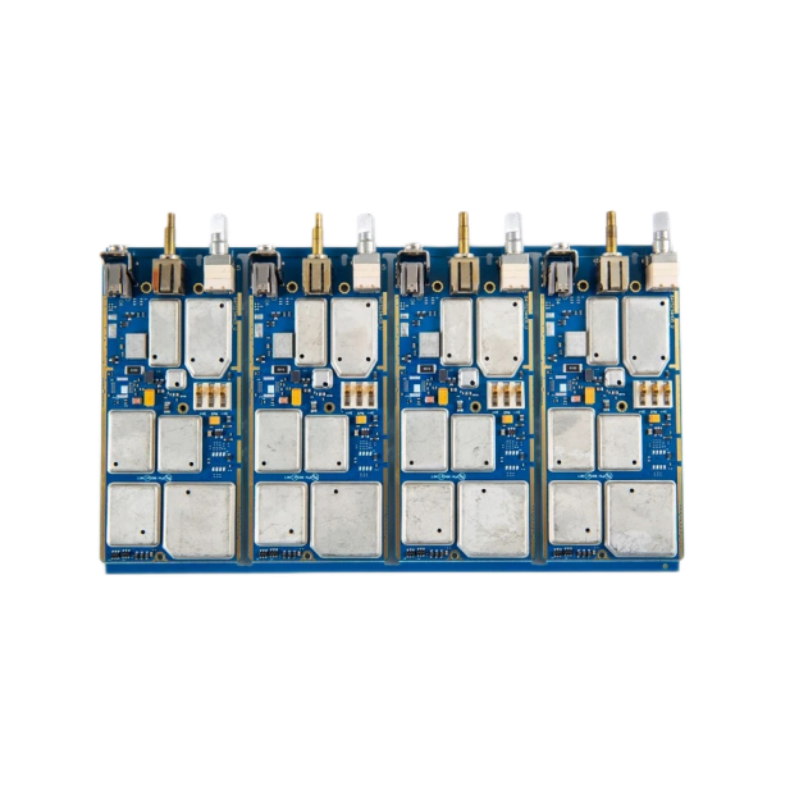

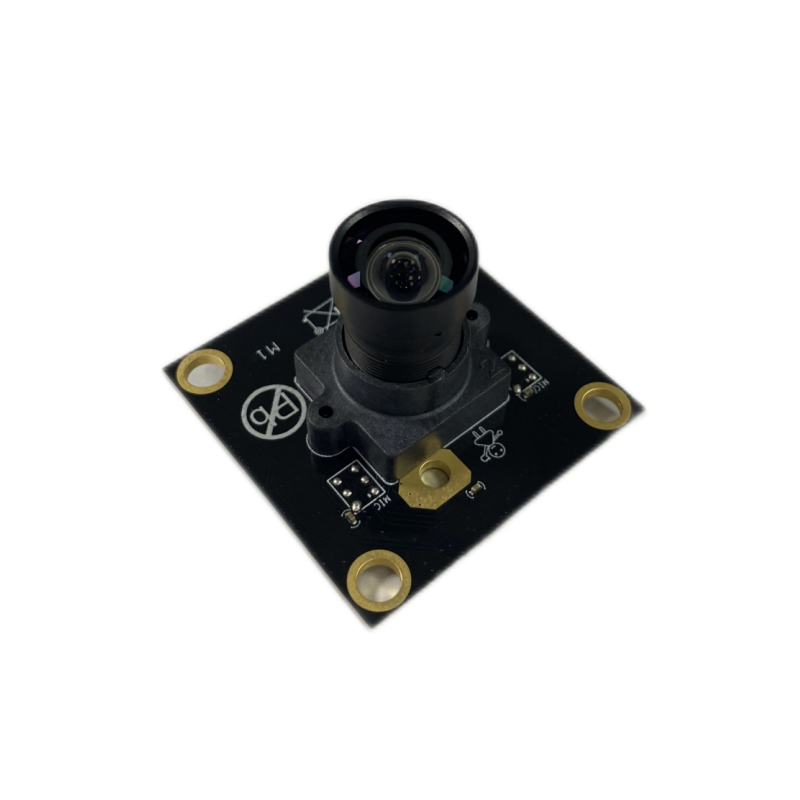

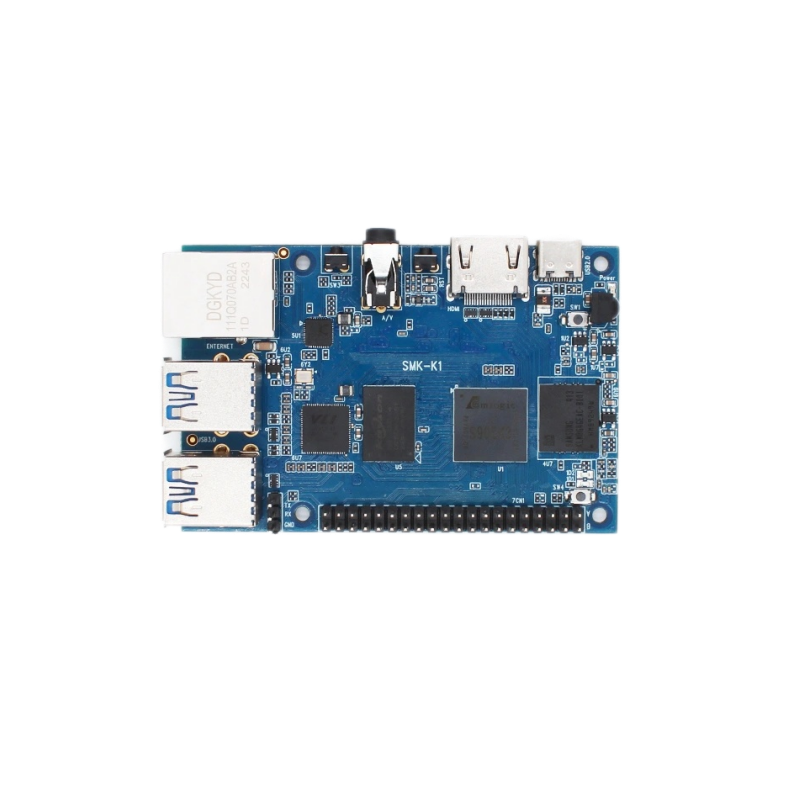

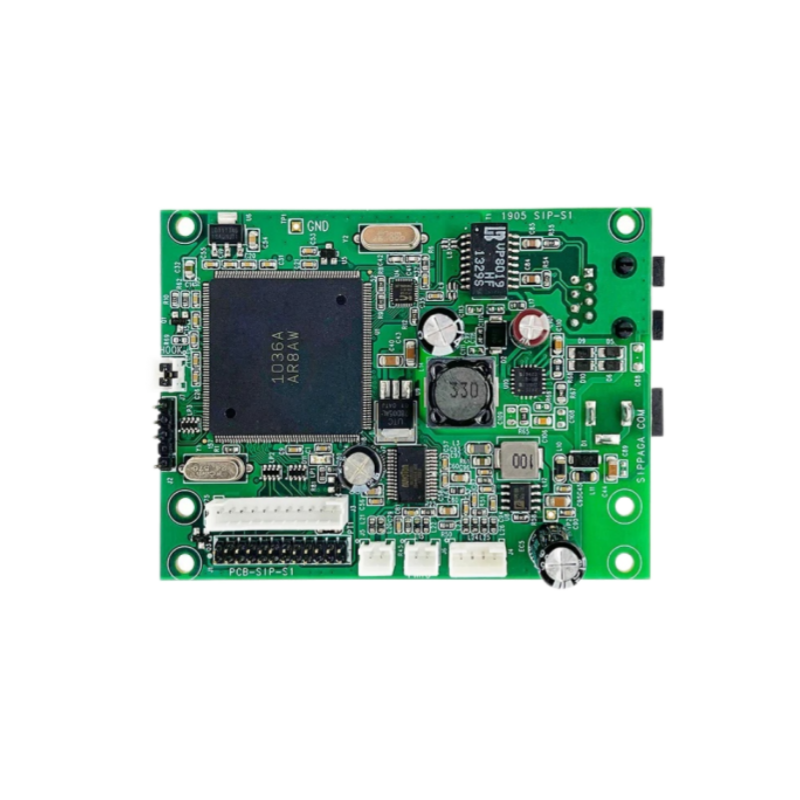

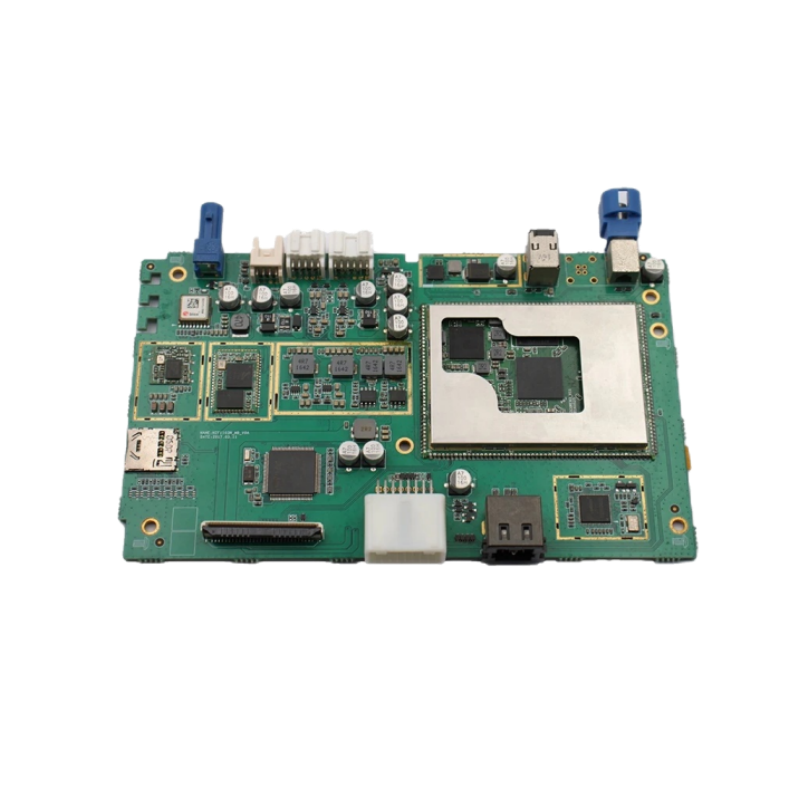

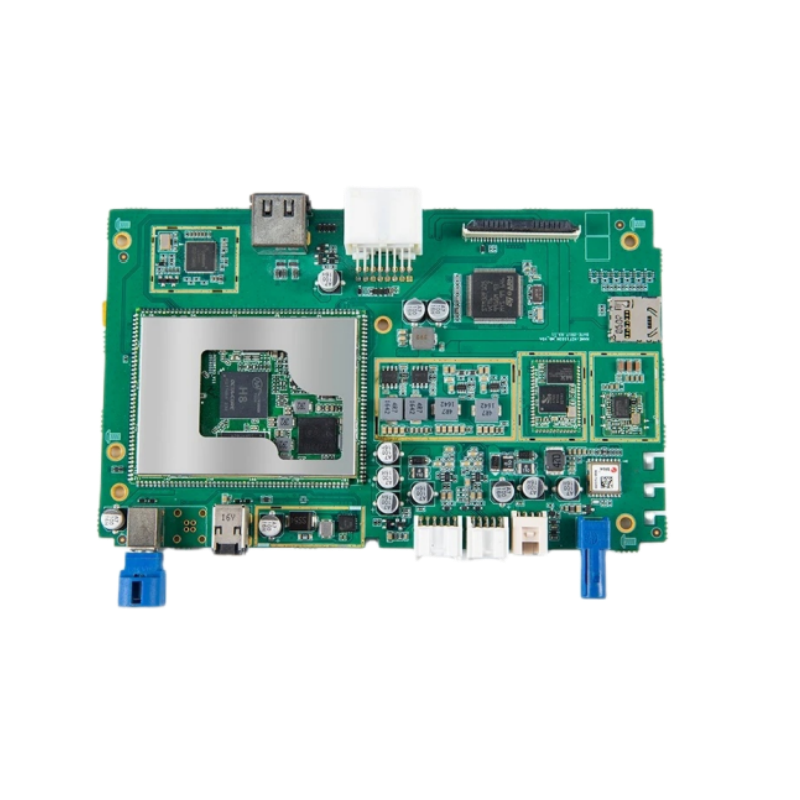

Since its establishment in 2008, Wells has served many leading enterprises in various industries at home and abroad. We can not only provide customers with industrial all-in-one computers, Industrial Panel PC, set-top boxes, development boards and cameras, but also meet their OEM demands.

shirly wellspcb

shirly wellspcb  shirley@wellspcba.com

shirley@wellspcba.com